A comparison of corrosion inhibitors for water-based TC® cooling lubricants vs. C11/C12 dicarboxylic acid mixtures

In many formulations for today’s cooling lubricants, water is used as the solvent of choice. Corrosion inhibitors represent a key component in such formulations. Alkanolamines such as TEA*, MIPA* and MEA* help to activate corrosion inhibitors and make them water-soluble.

Chemically speaking, these corrosion inhibitors are classified as carboxylic acids. This is not to mention the technical applications for corrosion inhibitors, including:

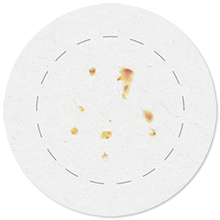

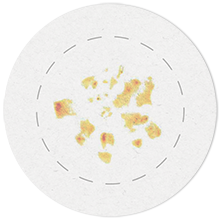

The corrosion test method pursuant to DIN 51 360 is used to quickly evaluate the effectiveness of water-miscible corrosion inhibitors.

Under clearly specified testing conditions, grey cast-iron chips are subjected to a controlled corrosion process on white filter papers. The corrosion inhibitors’ effectiveness is determined by the size and quality of corrosion stains on the filter paper (rust formation).

| TC® (2% solution) | C11/C12 dicarboxylic acid mixtures (2% solution) |

|---|---|

| 25% TC® 50 50% TEA* 25% Water | |

|  |

| 25% TC® 50 50% MIPA* 25% Water | |

|  |

| 25% TC® 50 50% MEA* 25% Water | |

|  |

*MEA: monoethanolamine, TEA: triethanolamine, MIPA: monoisopropylamine

The test clearly reveals consistently smaller and fewer stains on the filter paper when TC® 50 is used as a corrosion inhibitor.

Regardless of the amino alcohol used, triazine-based corrosion inhibitors perform better than the C11/C12 dicarboxylic acid mixture.

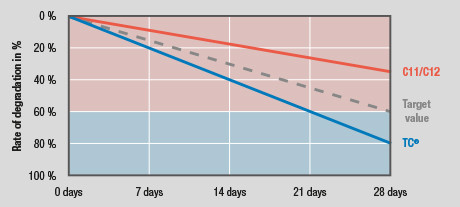

The environmental compatibility of a substance is determined based on its biodegradability. The OECD 301 test method is a generally accepted procedure for establishing biodegradability.

Something is deemed readily biodegradable if 60% of the test substance has broken down after 28 days (target value).

Note: Both products − TC® 50 and the C11/C12 dicarboxylic acid mixture − were tested in dissolved form (TEA salts).

After a period of 28 days, TC® displays a degradation rate of more than 80% (OECD 301 B, CO2 method), which fulfils the criterion of ready biodegradability.

The C11/C12 dicarboxylic acid mixture, on the other hand, has a significantly lower degradation rate (< 40%).

When compared to the C11/C12 dicarboxylic acid mixture, Metall-Chemie’s range of TC® provides the following benefits.